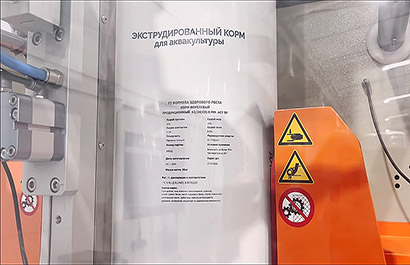

Company "BITimpex Anstalt LTD" launched a plant for the production of extruded fish feed for salmon, sturgeon, whitefish and catfish species (floating, sinking, slow-sinking feed). The plant's capacity is 60,000 tons per year. The plant is located on the territory of the Closed Water Supply Installation for growing Australian red-claw crayfish.

The feed contains: minced fish, minced meat, fish meal, blood meal, meat and bone meal, fish oil, wheat, corn gluten, vitamins, soybean meal, sunflower meal, rapeseed meal, yeast.

In the feed company "BITimpex Anstalt LTD" biologically active additives are introduced that strengthen the immunity of fish and also increase their resistance to diseases. Immunostimulant beta-glucan, vitamins C and E, vitamin premix, maintain fish in good condition.

In addition, a complex of amino acids is introduced into the feed, significantly increasing the survival rate and enhancing the growth of larvae and juvenile fish.

Scientific reports on feeding results can be found below.

Starter fish feeds are produced in the form of grains of the following sizes: 0.2–0.4 mm; 0.4–0.6 mm; 0.6–1 mm; 1–1.5 mm.

Production fish feed is produced in the form of granules of the following sizes: 2.5 mm; 3.5 mm; 4-5 mm, 6-8 mm.

Quality control of the feed produced in batches is carried out by certified laboratories: the State Scientific Center of the Russian Federation of Azov Black Sea Branch, the All-Russian Research Institute of Fisheries and Oceanology and the laboratory complex of veterinary and sanitary examination based on Rospotrebnadzor in the Republic of Crimea. Quality control of products is carried out both during the production process and after receiving the finished product.

Production feed for growing sturgeon, salmon, whitefish, and catfish species of fish.

Food type: fully extruded, sinking, slow-sinking and floating.

Granule size: 2.5 mm; 3.5 mm; 4-5 mm, 6-8 mm.

Ingredients: minced fish, meat and bone meal, fish meal, wheat, fish oil, soybean meal, corn gluten, yeast, vitamins, immunostimulant (beta-glucan), amino acid complex that increases survival and growth.

Package

— Polypropylene bag 20 – 25 kg;

— Plastic container 5 – 10 l.

(The composition of the feed, as well as the actual content of carbohydrates, fiber, ash and phosphorus in the feed, may change depending on natural fluctuations in the nutritional value of the raw materials).

Shelf life and storage conditions: 12 months from the date of production, provided that the packaging remains intact. The feed is packed in 25-kilogram multilayer polyethylene bags with perforation and anti-slip coating. Store in a dry, dark place at a temperature of 5 to 25 ° C. After opening the package, the feed should be stored for no more than 1 month.

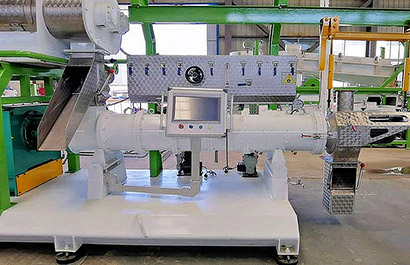

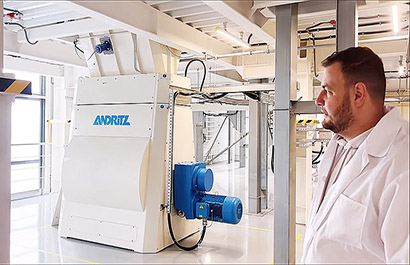

Our fish feed factories are equipped with the latest technological equipment from German and Finnish manufacturers.

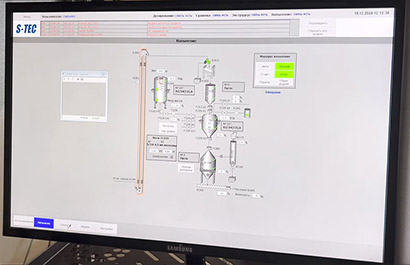

The fish feed production plant includes several separate machines for transportation, dosing, pre-treatment and subsequent cooling and storage.

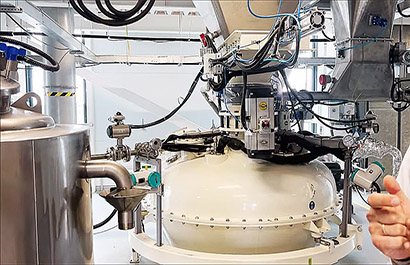

In our KAHL vacuum plant, fish pellets are cleaned of fats and liquids. The sequence of the individual process steps in the vacuum plant can be monitored and recreated by the operator. As a result, the parameters can be adjusted based on the properties or formula of the extrudate. This applies in particular to the important steps of liquid dosing, vacuum breaking, sequence and speed of the coating plant. In this way, the saturation level of the liquids in the product, the production of fine particles and the throughput can be optimized.

Continuous quality control of finished products is ensured by the batch traceability software system. It is the basis for total quality management and allows storing more than 1,000 formulas and tracking production data. With continuous batch labeling in the process database, it is possible to track which production adjustment was selected at what time. By storing the sampling times, laboratory analysis results can be correlated with accurate production data.

Stainless steel belt dryer with variable layer level and holding time. Gentle drying with adaptation of drying parameters to different granule sizes.

Coating system for applying oils, fats and micro-components in atmosphere or vacuum.

Device for grinding feed for young animals from 0.1 mm to 2 mm

In addition to the process and plant design for the entire line, KAHL provides comprehensive advice and support regarding the basic formulas and raw materials to be used, as well as intensive training of the operating personnel.