Bronze for monuments

- NON-FERROUS METALS

- General information

- About us

- Rolled BRONZE

- Rolled bronze

- Bronze powder

- Bronze powder BPO

- Bronze powder BOD

- Rolled bronze

- Bronze ribbon BrB2

- Bronze pipes

- Pipe bronze BrAZHN 10-4-4

- Bronze pipes BrAZhMts 10-3-1,5

- Bronze foil

- Bronze rods

- Bronze circles BrAMts 9-2

- Bronze Circle BrAZhMts10-3-1,5

- Bronze Circle Braze 9-4

- Bronze wire rods BrOTsS 5-5-5

- Bronze bars BrOF10-1

- Bronze rodBraZH 10-3

- Bronze sheets

- Bronze sheet BrH1

- Bronze sheet BrH1Tsr

- Bronze sheet BrH0,8Sh

- Bronze sheet BrH0,8T

- Bronze plate BrB

- Bronze strip BrB2

- Bronze wire BrAZh10-1,5

- Hexagonal bronze BRaZH 9-4

- Aluminum bronze ingots

- Aluminum bronze ingots

- Bronze BrAZH 9-4

- Bronze BrAZhMts 10-3-1,5

- Beryllium bronze BrB2

- Bronze BrAMts 9-2

- BROF Bronze 7-0,2

- Bronze BrOF10-1

- Bronze for monuments

- Silicon bronze

- Tin bronze OCS

- Bronze BrOTsS 5-5-5

- Bronze castings

- Chromium bronze BrH

News

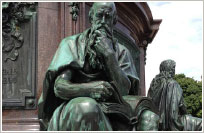

Bronze for monuments

Bronze is one of the most common materials for the manufacture of monuments. This is due to chemical and physical properties that make the master, is made a monument, it is easy to create sophisticated shapes with elegant details. In the manufacture of monuments in bronze is used as a raw material in bars.

In the production sites often use a tin foundry bronze ingots. This type of bronze should comply with GOST 614. BrO6Ts6S2h is a popular bronze monuments mark. pig weight should not be more than 42 kg, the shape and size can vary depending on the specific order.

Permissible number of components and standards of impurities consisting of:

- Tin - 5.0-7.0%;

- Zinc - 5.0-7.0%;

- Lead - 1.0-4.0%

- Antimony is not more than 0.5%;

- The iron is not more than 0.5%;

- Aluminum is not more than 0.1%;

- Total impurities not more than 1.0%

Bronze different wear resistance and increased corrosion resistance, is not sensitive to overheating and frost resistant. The disadvantage is the cost, because of the presence in the composition of the price slightly higher than the tin. But the casting of bronze tinless turns with greater shrinkage and loose. Bronze for monuments is not susceptible to external stimuli, natural, moisture, wind, etc.

In the bronze patina may occur over time. Many art lovers believe that it does not spoil the monuments and other items made of bronze, and even gives them a certain charm. If necessary, to get rid of the patina with strong acid solution (sulfuric acid, hydrochloric acid, sodium hydroxide solution). But do not forget that the constant exposure highly concentrated formulations bronze she may darken. You can also clean the brine or simply wipe with soap and water, if desired monuments of bronze.

|

|

|

|

|

|

|

|