Bronze wire BrAZh10-1,5

- NON-FERROUS METALS

- General information

- About us

- Rolled BRONZE

- Rolled bronze

- Bronze powder

- Bronze powder BPO

- Bronze powder BOD

- Rolled bronze

- Bronze ribbon BrB2

- Bronze pipes

- Pipe bronze BrAZHN 10-4-4

- Bronze pipes BrAZhMts 10-3-1,5

- Bronze foil

- Bronze rods

- Bronze circles BrAMts 9-2

- Bronze Circle BrAZhMts10-3-1,5

- Bronze Circle Braze 9-4

- Bronze wire rods BrOTsS 5-5-5

- Bronze bars BrOF10-1

- Bronze rodBraZH 10-3

- Bronze sheets

- Bronze sheet BrH1

- Bronze sheet BrH1Tsr

- Bronze sheet BrH0,8Sh

- Bronze sheet BrH0,8T

- Bronze plate BrB

- Bronze strip BrB2

- Bronze wire BrAZh10-1,5

- Hexagonal bronze BRaZH 9-4

- Aluminum bronze ingots

- Aluminum bronze ingots

- Bronze BrAZH 9-4

- Bronze BrAZhMts 10-3-1,5

- Beryllium bronze BrB2

- Bronze BrAMts 9-2

- BROF Bronze 7-0,2

- Bronze BrOF10-1

- Bronze for monuments

- Silicon bronze

- Tin bronze OCS

- Bronze BrOTsS 5-5-5

- Bronze castings

- Chromium bronze BrH

News

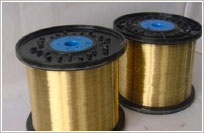

Bronze wire BrAZh10-1,5

The alloy of copper with aluminum is superior to common tin bronze in strength and heat resistance. Aluminum bronze perfectly handled the pressure. Of course, they are not without drawbacks, such as poor corrosion resistance in superheated steam. To solve this problem, the alloys are subjected to doping with iron, nickel, etc., and additional strength achieved aging at a temperature of 250-300 c. for three hours after hardening.

When the aluminum content of the alloy is higher than 7%, the ductility of aluminum bronzes is significantly reduced. This drawback is also eliminated by adding iron bronze structure significantly improves anti-friction and mechanical properties of the alloy.

One of the most common materials in the non-ferrous metal wire is a bronze BrAZh10-1,5 brand. BrAZh10-1,5 bronze wire has a high specific strength. Produced by the pressure in the cold and hot material. By thermal properties BrAZh10-1,5 relates to heat-resistant type bronzes thermal conductivity - 0.14-0.17 cal / cm * s * Castle.

According to the type of wire cross section is divided into two types:

1. Wire circular cross-section.

2. Wire square.

Wire BrAZh10-1.5 bronze is corrosion resistant, flexible, durable plastic and tensile material with excellent electrical conductivity. Mass it is demanded in electrical cable production, wires and coils, as well as in transport engineering.

Trading bronze BrAZh10-1,5 wire supplied in coils or coils.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|