Plywood

- Wood

- Oak

- Acacia

- Birch

- Pine

- Spruce

- Cypress

- Larch

- Cherry

- Nut

- Cedar

- Fir

- Beech

- Maple

- Linden

- Aspen

- Ash

- Alder

- Veneer

- Pallet Billet

- Plywood

- Parquet

- Plant for the production of OSB, chipboard, fiberboard

- Plywood and MDF factories

- Plants for the production of wall panels and siding

- Factories for the production of sandwich panels and roofing

News

Plywood

MDF is an environmentally friendly material. The main binder acts are not synthetic but natural material. Constitute the basis of MDF dried wood fibers treated with special binders. Abbreviation MDF stands for Medium Density Fiberboard. MDF is tolerating to differences of humidity, not swell or warp. They have high mechanical strength, which allows the use of MDF for furniture, doors, wall panels and others. Another feature of the plates they are resistance to various fungi and microorganisms, which make products from MDF hygiene and safety in the home.

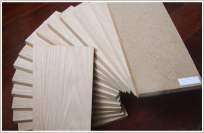

Particle Board (chipboard) is the most popular among the plate materials. Made from low-value wood both softwood and hardwood. Due to the special additives, particleboard is a strong and durable material. Notch plate devoid scratches, stains, and their smooth edges, thickness from 10 to 26 mm. Such material ready for furniture production. Another important property of chipboard is ease of processing: the plate well to sawing, drilling, planing, easily glued and painted; and on some physical and mechanical properties of this material is superior to natural wood: less plate swell from moisture, less flammable, have good heat and sound insulating properties. It only remains to add that such a high quality particleboard meets the low cost.

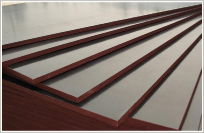

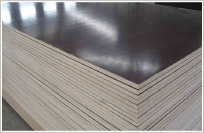

Water resistant plywood is an eco-friendly high-quality material with a high level of water resistance. This brand produced by gluing plywood interperpendicular veneers of different kinds of wood (birch, alder or combination) using formaldehyde resins. The multilayer structure with multi-directional fibers of wood in different layers of the material provides resistance to deformation, and safe for human adhesive composition forms a final product, characterized by high durability and quality. As a result, in addition to affordable prices, among the main advantages of water resistant plywood. Thanks to the universal indicators of reliability and durability, water resistant plywood has a wide scope of its use. It is equally successfully used for internal and external works, aircraft modeling and furniture industry, in the field of outdoor advertising and frame construction, furnishing floor indoors and as supplementary material for the manufacture of boats.

More information and product specifications can be found in the Wood Catalogue.

|

Ash Furniture Plywood 1250x1250, 1525x1525, 1250x2500 |

Beech Multilayer Plywood 1250x1250, 1525x1525, 1250x2500 |

Cedar Furniture Plywood 1250x1250, 1525x1525, 1250x2500 |

|

Cherry Furniture Plywood 1250x2500 |

Spruce Plywood |

Furniture Multilayer Plywood 1250x1250, 1525x1525, 1250x2500 |

|

Cedar Plywood |

Particle Board 1250x1250, 1525x1525, 1250x2500 |

Oak Furniture Multilayer Plywood |

|

Nut Multilayer Plywood |

Beech Plywood |

Aspen Plywood |

|

Packaging Department |

Packaging Department |

Packaging Department |

|

Medium Density |

Cherry Medium Density Fibre Board |

Plywood Production

|

|

Red Ash plywood |

Birch plywood |

Cherry plywood |

|

Water Resistant Multilayer Plywood

|

Water Resistant Multilayer Plywood 1250x1250, 1525x1525, 1250x2500 |

Water Resistant Multilayer Plywood 1250x1250, 1525x1525, 1250x2500 |

|

Water Resistant Plywood

|

White Ash Medium Density Fibre Board |

White Furniture Ash Medium Density Fibre Board |

|

White Poplar Plywood 1250x2500

|

White Horn-beech Plywood 1250x1250, 1525x1525, 1250x2500 |

White Birch Multilayer Plywood 1250x1250, 1525x1525, 1250x2500 |

|

Yellow Ash Medium Density Fibre Board 1250x2500, 1250x1250 |

Red Oak Medium Density Fibre Board |

Red Oak Medium Density Fibre Board |