Aluminum form

- NON-FERROUS METALS

- General information

- About us

- Rolled ALUMINIUM

- Aluminium 1561

- Aluminium 6061 (AD33)

- AluminiumA5

- Aluminium A7

- Aluminium AB87

- Aluminium AD31

- Aluminium AK12

- Aluminium AlMg (aluminum-magnesium alloy)

- High purity aluminum A999

- Aluminium A995

- High purity aluminum A999

- Primary aluminum A99

- Casting aluminum alloys

- Aluminium AK5M2

- Balls made of aluminum

- Electrodes for aluminum welding

- Rolled aluminum

- Aluminium roofing

- Aluminium grits AKV

- Aluminium tape

- Aluminum tape 1105AM

- Aluminum tape AD1N

- Aluminum form

- Aluminum plate D16

- Aluminum strip

- Aluminum electrical bus

- Aluminum bus AD0

- Aluminum bus AD31T

- Aluminum wire

- Aluminium rolled wire

- Aluminium wire for welding

- Aluminum wire AD1

- Enameled aluminum

- Aluminum mesh

- Aluminium granules

- Aluminium sheets

- Aluminum sheet AD1N -AD1 -AD1M

- Aluminum sheet AMg2M -AMg2 -AMg2NR

- Aluminum sheet AMg3M -AMg3

- Aluminum sheet AMg5M -AMg5

- Aluminum sheet AMg6BM

- Aluminum sheet AMtsM -AMts

- Aluminum sheet D16AT -D16AM -D16

- Aluminum corrugated sheet

- Aluminum decking

- Aluminium rolls

- Decorative aluminum sheet

- Perforated aluminum panels

- Brushed aluminum

- Sheets made of aluminum 1105 -1105AM

- Food aluminum sheet A5Ms -A5

- Aluminium profiles

- Aluminum mounting profile

- Aluminum profile of civil construction

- Aluminum I-beam

- Aluminum profile for drywall

- Aluminum profile for wardrobes

- Aluminum brands

- Aluminum channel

- Structural aluminum profile

- Aluminium profiles for partition

- Aluminium profiles for facades

- U-shaped aluminum profile

- Ebb aluminum

- Industrial aluminum profile

- Aluminium area

- Small perforated aluminum

- Aluminum powder PAP-1

- Aluminum paste GPB1

- aluminum powder ASD-4

- Aluminum powder PAP-1

- Protectors aluminum

- Aluminum square

- Circle aluminum

- Aluminium rod AMg

- Rod aluminum D16T -D16

- Hexagonal aluminum

- Pipes of aluminum alloys

- Aluminum pipe profile

- Aluminium rectangular tube

- Square aluminum tube

- Aluminum drill pipe

- Retraction aluminum

- Aluminum Pipe AMg

- Pipe aluminum D16T

- Aluminum seamless pipe

- Thin-walled aluminum tube

- Aluminum pipe of large diameter

- Aluminum round pipe

- Aluminum pipe AD31

- Thick-walled aluminum tube

- Aluminium corrugated tubes

- Perforated stainless pipe

- Aluminum tubes

- Chushka aluminum

- Aluminum castings

News

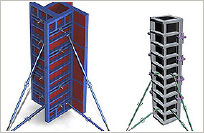

Aluminum form

Aluminum form - a kind of frame-panel formwork systems used in the construction of reinforced concrete. The benefits that aluminum form has to steel counterparts - a smaller proportion of 1m2 shuttering frame (easier installation), corrosion resistance. Aluminum form is a frame modular panels. Dimensions of boards due to the parameters of the manufacturer or individually designed for a specific project. Shields can be either straight (flat) and spatial (angular or radial). Generally, aluminum panels manufactured shuttering small dimensions (up to 3.3 m) for the convenience of transportation and installation. Enlargement boards going in place. The main elements that make up the formwork aluminum:

aluminum frame - the majority of producers consists of a closed thin-walled (2-3 mm) of the profile complicated cross-section, the approximate to the square, at least - a lightweight version of the brackets (designed for smaller loads);

working surface (deck) - Laminated pressed birch plywood 18mm (at least - composite materials or PVC sheet), is attached to the aluminum frame with screws, place sealed joints;

locking wedge - the fastening element for connection of two adjacent shuttering panels aluminum;

screw coupling nut shrink - fixing elements opposed shields. Aluminum decking has the following parameters:

frame material - aluminum profile;

The average specific weight - 30 kg / m2;

Design load - 60-100 kPa;

The deflection at the maximum permissible load - 1/350;

The turnover of the working surface - up to 100 cycles;

Turnover frames - up to 450 cycles;

Thickness Profile - 2-3 mm;

panel width - from 0.25 m to 1.5 m;

board height - from 0.3m to 3,3m;

Transport and storage - in bundles no more than 10 pieces.

|

|

|

|

|

|

|

|

|

|

|