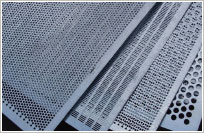

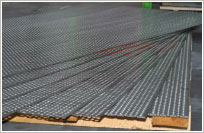

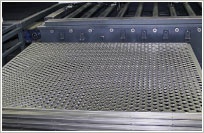

Perforated aluminum panels

- NON-FERROUS METALS

- General information

- About us

- Rolled ALUMINIUM

- Aluminium 1561

- Aluminium 6061 (AD33)

- AluminiumA5

- Aluminium A7

- Aluminium AB87

- Aluminium AD31

- Aluminium AK12

- Aluminium AlMg (aluminum-magnesium alloy)

- High purity aluminum A999

- Aluminium A995

- High purity aluminum A999

- Primary aluminum A99

- Casting aluminum alloys

- Aluminium AK5M2

- Balls made of aluminum

- Electrodes for aluminum welding

- Rolled aluminum

- Aluminium roofing

- Aluminium grits AKV

- Aluminium tape

- Aluminum tape 1105AM

- Aluminum tape AD1N

- Aluminum form

- Aluminum plate D16

- Aluminum strip

- Aluminum electrical bus

- Aluminum bus AD0

- Aluminum bus AD31T

- Aluminum wire

- Aluminium rolled wire

- Aluminium wire for welding

- Aluminum wire AD1

- Enameled aluminum

- Aluminum mesh

- Aluminium granules

- Aluminium sheets

- Aluminum sheet AD1N -AD1 -AD1M

- Aluminum sheet AMg2M -AMg2 -AMg2NR

- Aluminum sheet AMg3M -AMg3

- Aluminum sheet AMg5M -AMg5

- Aluminum sheet AMg6BM

- Aluminum sheet AMtsM -AMts

- Aluminum sheet D16AT -D16AM -D16

- Aluminum corrugated sheet

- Aluminum decking

- Aluminium rolls

- Decorative aluminum sheet

- Perforated aluminum panels

- Brushed aluminum

- Sheets made of aluminum 1105 -1105AM

- Food aluminum sheet A5Ms -A5

- Aluminium profiles

- Aluminum mounting profile

- Aluminum profile of civil construction

- Aluminum I-beam

- Aluminum profile for drywall

- Aluminum profile for wardrobes

- Aluminum brands

- Aluminum channel

- Structural aluminum profile

- Aluminium profiles for partition

- Aluminium profiles for facades

- U-shaped aluminum profile

- Ebb aluminum

- Industrial aluminum profile

- Aluminium area

- Small perforated aluminum

- Aluminum powder PAP-1

- Aluminum paste GPB1

- aluminum powder ASD-4

- Aluminum powder PAP-1

- Protectors aluminum

- Aluminum square

- Circle aluminum

- Aluminium rod AMg

- Rod aluminum D16T -D16

- Hexagonal aluminum

- Pipes of aluminum alloys

- Aluminum pipe profile

- Aluminium rectangular tube

- Square aluminum tube

- Aluminum drill pipe

- Retraction aluminum

- Aluminum Pipe AMg

- Pipe aluminum D16T

- Aluminum seamless pipe

- Thin-walled aluminum tube

- Aluminum pipe of large diameter

- Aluminum round pipe

- Aluminum pipe AD31

- Thick-walled aluminum tube

- Aluminium corrugated tubes

- Perforated stainless pipe

- Aluminum tubes

- Chushka aluminum

- Aluminum castings

News

Perforated aluminum panels

Perforated aluminium panels is a special kind of product from any metal. It differs by the presence of a sheet of holes of variant shapes and sizes. The most commonly used perforated aluminium panels in design, because you can create a unique facades and interiors. Also often used in the creation of the outdoor advertising. Material production is determined by the task. The most versatile can be considered a perforated aluminum panels, which have the ability to sufficiently long operation due to high ductility and corrosion resistance. Features such sheets have not been established for sure - it depends on the manufacturer. Perforated aluminum panels have a standard sheet thickness of 2-4 mm. For example, a sheet of 3mm thickness has sufficient strength to be used for most jobs facade cladding. The maximum dimensions of such sheets have the same restrictions do not normalized, but are considered standard sheets 1000h2000 mm. Perforation also can be changed. The most common are all simple geometric shapes. In general, perforated aluminum panels - aluminum is perforated plates a specific shape, size, that are cut in a certain order. The finished product is resistant to corrosion, the corrosion can be further covered by a lacquer layer to protect against mechanical damage and oxidation. Scope huge for these materials. Perforated aluminum panels are used for the realization of the set design ideas are used in the design of advertising logos and proper outdoor advertising. The panels are also used for interior decoration of shops, offices and others.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|