Copper-nickel pipes

- NON-FERROUS METALS

- General information

- About us

- Rolled COPPER

- Rolled Copper

- Oxygen-Free copper

- Oxygen-free copper M0b

- Copper rod

- Copper rolled metal

- Copper seam roofing

- Copper metal roofing

- Copper shingles

- Copper roofing sheet

- KME copper roofing

- Copper roofing TECU

- Copper roofing M1f GOST 495

- Copper roll

- Roofing made of copper M1f GOST 1173

- Patinated copper TECU (oxidized copper)

- Other rolled cooper

- Copper wire

- Copper welding wire

- Tinned copper wire

- Wires copper winding

- Copper wire electrical

- Enameled copper wire (enameled wire)

- Copper square

- Copper profile

- Copper Angle

- Profiles of copper M1

- Profile Copper M2

- Copper rods

- Circle copper M1r

- Cooper circles M3

- Copper circles M2f

- Cooper rods M3R

- Copper circle M1f

- Rod copper M1

- Rod copper M2

- Copper hexagon

- Pipes made of copper

- Copper pipe GOST 21646

- Copper tube GOST 16774

- Copper pipe profile

- Copper pipe rectangula

- Copper-nickel pipes

- Copper pipes and fittings GOST R 52318

- Copper pipe for underfloor heatin

- Copper pipes for water supply

- Copper pipes for heating

- Copper pipe GOST 617

- Copper tubes annealed

- Copper pipe seamles

- Copper pipe annealed

- Copper pipe thick-walle

- Cooper thin-walled pipes

- Pipes made of copper GOST 2624

- Copper capillary pipes Group B

- Copper capillary pipes Group A

- Flat rolled copper

- Copper tape GOST 1173

- Tape Copper M2

- Tape copper electrical

- M1 Copper tape

- Soft copper tape M1

- Copper plate GOST 1173

- Copper plate M1

- Copper strip GOST 495

- Cooper band M1

- Copper foil GOST 5638

- Copper Foil M1

- Copper sheet GOST 495

- Copper sheet M1r

- Copper sheet M1r

- M2 Cooper sheets

- Copper ingot

- Copper MB (vacuum copper)

- Copper MK

- Electrical copper M1E

- Copper ingots

- M1 copper ingots

- Copper cathode

- Cathode copper m2K

- Copper cathodes M0k

- Copper cathodes M00k

- Copper Cathodes M1k

- Copper powde

- Copper nanopowder

- Copper powder superfine PMVD

- Ultrafine copper powder PMU and others

- Electrolytic copper powder

- ICP-1 Copper powder

- Cooper grid

- The alloy of copper-phosphorous

- Copper phosphorous MF9

- Phosphor copper MF10

News

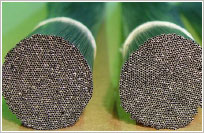

Copper-nickel pipes

Copper-nickel tubes are useful in many types of marine engineering services in heating circuits, refrigeration, fuel wires liquid fuel gas supply. If necessary, a copper-nickel tubes easily and securely connect the high-temperature soldering. Produces copper-nickel tubes of high quality alloys and, despite the high cost, in high demand. The main advantages of copper-nickel tubes - durability (service life of 40-80 years); Corrosion; They refractory; withstand operating temperatures of 250 � C and a pressure of 200 atmospheres; resistance to damage hydraulic and vibration; easy installation. Nominal size of the copper-nickel pipe is from 6 to 260 mm, wall thickness from 1 to 10 mm, length from 2 to 6 meters. The composition and the percentage of impurities for copper-nickel tubes defines the brand of copper-nickel alloy. They are made of copper-nickel alloy pipe often, brand MNZH5-1, corresponds to GOST 17217-79, which applies to cold-pressed and tubes that are used in the shipbuilding industry. These copper-nickel tubes have excellent mechanical properties that are not amenable to deformation in hot and cold conditions. The alloy contains MNZH5-1 supplements of iron and manganese, so it is not prone to cracking and is strong enough so you can use pipes in offshore pipelines. Quality control of the copper-nickel tubes is carried out at all stages of production, they are subject to rigorous quality control. Tubes delivered in coils of 15 m and 30 m. Coils are packed in a plastic film that allows the transport pipe without damage and deformation, while maintaining the initial operating parameters.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|