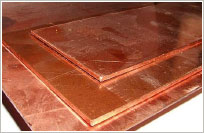

Copper sheet M1r

- NON-FERROUS METALS

- General information

- About us

- Rolled COPPER

- Rolled Copper

- Oxygen-Free copper

- Oxygen-free copper M0b

- Copper rod

- Copper rolled metal

- Copper seam roofing

- Copper metal roofing

- Copper shingles

- Copper roofing sheet

- KME copper roofing

- Copper roofing TECU

- Copper roofing M1f GOST 495

- Copper roll

- Roofing made of copper M1f GOST 1173

- Patinated copper TECU (oxidized copper)

- Other rolled cooper

- Copper wire

- Copper welding wire

- Tinned copper wire

- Wires copper winding

- Copper wire electrical

- Enameled copper wire (enameled wire)

- Copper square

- Copper profile

- Copper Angle

- Profiles of copper M1

- Profile Copper M2

- Copper rods

- Circle copper M1r

- Cooper circles M3

- Copper circles M2f

- Cooper rods M3R

- Copper circle M1f

- Rod copper M1

- Rod copper M2

- Copper hexagon

- Pipes made of copper

- Copper pipe GOST 21646

- Copper tube GOST 16774

- Copper pipe profile

- Copper pipe rectangula

- Copper-nickel pipes

- Copper pipes and fittings GOST R 52318

- Copper pipe for underfloor heatin

- Copper pipes for water supply

- Copper pipes for heating

- Copper pipe GOST 617

- Copper tubes annealed

- Copper pipe seamles

- Copper pipe annealed

- Copper pipe thick-walle

- Cooper thin-walled pipes

- Pipes made of copper GOST 2624

- Copper capillary pipes Group B

- Copper capillary pipes Group A

- Flat rolled copper

- Copper tape GOST 1173

- Tape Copper M2

- Tape copper electrical

- M1 Copper tape

- Soft copper tape M1

- Copper plate GOST 1173

- Copper plate M1

- Copper strip GOST 495

- Cooper band M1

- Copper foil GOST 5638

- Copper Foil M1

- Copper sheet GOST 495

- Copper sheet M1r

- Copper sheet M1r

- M2 Cooper sheets

- Copper ingot

- Copper MB (vacuum copper)

- Copper MK

- Electrical copper M1E

- Copper ingots

- M1 copper ingots

- Copper cathode

- Cathode copper m2K

- Copper cathodes M0k

- Copper cathodes M00k

- Copper Cathodes M1k

- Copper powde

- Copper nanopowder

- Copper powder superfine PMVD

- Ultrafine copper powder PMU and others

- Electrolytic copper powder

- ICP-1 Copper powder

- Cooper grid

- The alloy of copper-phosphorous

- Copper phosphorous MF9

- Phosphor copper MF10

News

Copper sheet M1r

Copper sheet - a traditional building material, which is used in the repair and construction for decades. Due to their resistance to environmental influences, copper has good corrosion resistance.

For the production of copper sheets used raw materials of different brands: M0, M1, M2, M3 and several others. The number in the mark indicates the purity. For example, copper mark M0 must contain copper not less than 99.99%, and a mark M4 - 99%. Harmful impurities in the copper are considered to lead and bismuth - copper they make fragile, it loses elasticity, can crumble. The most applicable are trademarks of M1 or M0. Given that M0 a rare stamp, the copper sheet M1 - the best option to use.

Copper sheet itself is plastic, lightweight, environmentally friendly material which is easy to work and therefore can be used in different areas:

- For the construction of various building structures (eg, facade work);

- In the production of HVAC equipment;

- For the manufacture of conductors;

- As a roofing material.

It produces copper sheet in different ways, which determines its durability, appearance and brand. The main methods of manufacturing copper sheet: cold and hot. Ready material may have two degrees of strength: normal and high.

Unlike other building materials, copper sheet not need to be painted or otherwise treated. It can be easy to mount, for example, put on the roof, fix and leave for a certain number of years. For the first few years of copper will change its color from fiery red to dark brown, almost black. After that, it will begin to acquire a greenish patina as a surface veil (patina, formed by the oxidation of copper), which will be protected from the effects of the environment.

|

|

|

|

|

|

|

|

|

|

|