Flat rolled copper

- NON-FERROUS METALS

- General information

- About us

- Rolled COPPER

- Rolled Copper

- Oxygen-Free copper

- Oxygen-free copper M0b

- Copper rod

- Copper rolled metal

- Copper seam roofing

- Copper metal roofing

- Copper shingles

- Copper roofing sheet

- KME copper roofing

- Copper roofing TECU

- Copper roofing M1f GOST 495

- Copper roll

- Roofing made of copper M1f GOST 1173

- Patinated copper TECU (oxidized copper)

- Other rolled cooper

- Copper wire

- Copper welding wire

- Tinned copper wire

- Wires copper winding

- Copper wire electrical

- Enameled copper wire (enameled wire)

- Copper square

- Copper profile

- Copper Angle

- Profiles of copper M1

- Profile Copper M2

- Copper rods

- Circle copper M1r

- Cooper circles M3

- Copper circles M2f

- Cooper rods M3R

- Copper circle M1f

- Rod copper M1

- Rod copper M2

- Copper hexagon

- Pipes made of copper

- Copper pipe GOST 21646

- Copper tube GOST 16774

- Copper pipe profile

- Copper pipe rectangula

- Copper-nickel pipes

- Copper pipes and fittings GOST R 52318

- Copper pipe for underfloor heatin

- Copper pipes for water supply

- Copper pipes for heating

- Copper pipe GOST 617

- Copper tubes annealed

- Copper pipe seamles

- Copper pipe annealed

- Copper pipe thick-walle

- Cooper thin-walled pipes

- Pipes made of copper GOST 2624

- Copper capillary pipes Group B

- Copper capillary pipes Group A

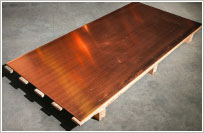

- Flat rolled copper

- Copper tape GOST 1173

- Tape Copper M2

- Tape copper electrical

- M1 Copper tape

- Soft copper tape M1

- Copper plate GOST 1173

- Copper plate M1

- Copper strip GOST 495

- Cooper band M1

- Copper foil GOST 5638

- Copper Foil M1

- Copper sheet GOST 495

- Copper sheet M1r

- Copper sheet M1r

- M2 Cooper sheets

- Copper ingot

- Copper MB (vacuum copper)

- Copper MK

- Electrical copper M1E

- Copper ingots

- M1 copper ingots

- Copper cathode

- Cathode copper m2K

- Copper cathodes M0k

- Copper cathodes M00k

- Copper Cathodes M1k

- Copper powde

- Copper nanopowder

- Copper powder superfine PMVD

- Ultrafine copper powder PMU and others

- Electrolytic copper powder

- ICP-1 Copper powder

- Cooper grid

- The alloy of copper-phosphorous

- Copper phosphorous MF9

- Phosphor copper MF10

News

Flat rolled copper

In an industrial scale rolled copper is most commonly used in mechanical engineering, the automotive industry, in special metalworking, as well as in the production of railway and electric transport. Due to the excellent processing properties of copper marks used in the production of rolled products, and the latter can be used in the chemical and petroleum industries.

In the industrial market of non-ferrous metal rolled copper flat products represented by the following types:

- Copper belts. Flat Rolled steel supplied in rolls / coils.

- A standard size sheets 600h1500 mm, the plate thickness of 0.5-50 mm.

- Strips. Flat-rolled copper strip with 0.4-6 mm thickness and a width of 40-100 mm.

- Foil Roll Technology. Thin flat steel of rectangular cross-section.

- Plates rectangular, normal and high accuracy in length and width.

- Ingots of rectangular and trapezoidal cross-section.

- Anodes. Supplied in the form of spheres, plates.

- Solders. Delivered in the form of rods, bars, strips.

The given types of products most often made of copper alloy grades M0, M1, M2, M3, and their modifications. The technical and operational characteristics depend on the percentage of impurities in the composition (oxygen, zinc, phosphorus and the like. D.).

To connect the sections of rolled metal products by rolling copper solder is used as solder. Certain additives and their quantity in percentage of alloy solder influence its technological properties. For example, to exclude the flux processing, which leads to additional costs, you can use copper-phosphorous solder, which itself already has a good property of flux. For lowering the melting temperature of the solder used copper and zinc, wherein the zinc content by percentage will depend on the desired strength and ductility.

|

|

|

|

|

|

|

|

|

|

|