Copper powde

- NON-FERROUS METALS

- General information

- About us

- Rolled COPPER

- Rolled Copper

- Oxygen-Free copper

- Oxygen-free copper M0b

- Copper rod

- Copper rolled metal

- Copper seam roofing

- Copper metal roofing

- Copper shingles

- Copper roofing sheet

- KME copper roofing

- Copper roofing TECU

- Copper roofing M1f GOST 495

- Copper roll

- Roofing made of copper M1f GOST 1173

- Patinated copper TECU (oxidized copper)

- Other rolled cooper

- Copper wire

- Copper welding wire

- Tinned copper wire

- Wires copper winding

- Copper wire electrical

- Enameled copper wire (enameled wire)

- Copper square

- Copper profile

- Copper Angle

- Profiles of copper M1

- Profile Copper M2

- Copper rods

- Circle copper M1r

- Cooper circles M3

- Copper circles M2f

- Cooper rods M3R

- Copper circle M1f

- Rod copper M1

- Rod copper M2

- Copper hexagon

- Pipes made of copper

- Copper pipe GOST 21646

- Copper tube GOST 16774

- Copper pipe profile

- Copper pipe rectangula

- Copper-nickel pipes

- Copper pipes and fittings GOST R 52318

- Copper pipe for underfloor heatin

- Copper pipes for water supply

- Copper pipes for heating

- Copper pipe GOST 617

- Copper tubes annealed

- Copper pipe seamles

- Copper pipe annealed

- Copper pipe thick-walle

- Cooper thin-walled pipes

- Pipes made of copper GOST 2624

- Copper capillary pipes Group B

- Copper capillary pipes Group A

- Flat rolled copper

- Copper tape GOST 1173

- Tape Copper M2

- Tape copper electrical

- M1 Copper tape

- Soft copper tape M1

- Copper plate GOST 1173

- Copper plate M1

- Copper strip GOST 495

- Cooper band M1

- Copper foil GOST 5638

- Copper Foil M1

- Copper sheet GOST 495

- Copper sheet M1r

- Copper sheet M1r

- M2 Cooper sheets

- Copper ingot

- Copper MB (vacuum copper)

- Copper MK

- Electrical copper M1E

- Copper ingots

- M1 copper ingots

- Copper cathode

- Cathode copper m2K

- Copper cathodes M0k

- Copper cathodes M00k

- Copper Cathodes M1k

- Copper powde

- Copper nanopowder

- Copper powder superfine PMVD

- Ultrafine copper powder PMU and others

- Electrolytic copper powder

- ICP-1 Copper powder

- Cooper grid

- The alloy of copper-phosphorous

- Copper phosphorous MF9

- Phosphor copper MF10

News

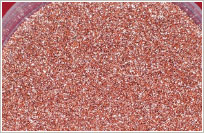

Copper powde

Now, with the volume of production of this type of products is constantly increasing every year, as copper powder, which is explained by the increase in demand. It represents the collection of microparticles of copper, which are often spherical in shape and size of which can vary depending on its grade and use. A powder often by spraying of copper in two ways: physical, chemical, or mechanical (crushing and grinding of large materials, dispersion and melt granulation).

In modern conditions the copper powder has found its application in various fields of national economy, including electrical engineering, instrument making, mechanical engineering, automotive, electronics and chemical industries. This type of product is practically irreplaceable in the production of all kinds of paints and varnishes in the press object of this metal in the manufacture of tires, solar cells, nanotechnology and other areas of production.

The process of manufacturing of copper powder itself of the production technology in our country is strictly regulated by GOST and TU. The finished product can have in their composition of impurities and clots.

Copper powder is marked depending on the physicochemical properties of the material. Thus distinguished:

PM - copper powder unstabilized;

ICP-1, ICP-A - copper powder stabilized;

PMS-K - copper powder stabilized konopatochnaya;

PMS-H - copper powder stabilized low dispersion.

Implemented by copper powder in a metal barrel, sealed plastic bag or double-PET. In addition, copper powder requires special conditions during storage and transport, namely, it must be protected from accidental moisture and reactive materials and acids. At the same temperature for storing powdered copper should not exceed 25 degrees Celsius.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|