Ultrafine copper powder PMU and others

- NON-FERROUS METALS

- General information

- About us

- Rolled COPPER

- Rolled Copper

- Oxygen-Free copper

- Oxygen-free copper M0b

- Copper rod

- Copper rolled metal

- Copper seam roofing

- Copper metal roofing

- Copper shingles

- Copper roofing sheet

- KME copper roofing

- Copper roofing TECU

- Copper roofing M1f GOST 495

- Copper roll

- Roofing made of copper M1f GOST 1173

- Patinated copper TECU (oxidized copper)

- Other rolled cooper

- Copper wire

- Copper welding wire

- Tinned copper wire

- Wires copper winding

- Copper wire electrical

- Enameled copper wire (enameled wire)

- Copper square

- Copper profile

- Copper Angle

- Profiles of copper M1

- Profile Copper M2

- Copper rods

- Circle copper M1r

- Cooper circles M3

- Copper circles M2f

- Cooper rods M3R

- Copper circle M1f

- Rod copper M1

- Rod copper M2

- Copper hexagon

- Pipes made of copper

- Copper pipe GOST 21646

- Copper tube GOST 16774

- Copper pipe profile

- Copper pipe rectangula

- Copper-nickel pipes

- Copper pipes and fittings GOST R 52318

- Copper pipe for underfloor heatin

- Copper pipes for water supply

- Copper pipes for heating

- Copper pipe GOST 617

- Copper tubes annealed

- Copper pipe seamles

- Copper pipe annealed

- Copper pipe thick-walle

- Cooper thin-walled pipes

- Pipes made of copper GOST 2624

- Copper capillary pipes Group B

- Copper capillary pipes Group A

- Flat rolled copper

- Copper tape GOST 1173

- Tape Copper M2

- Tape copper electrical

- M1 Copper tape

- Soft copper tape M1

- Copper plate GOST 1173

- Copper plate M1

- Copper strip GOST 495

- Cooper band M1

- Copper foil GOST 5638

- Copper Foil M1

- Copper sheet GOST 495

- Copper sheet M1r

- Copper sheet M1r

- M2 Cooper sheets

- Copper ingot

- Copper MB (vacuum copper)

- Copper MK

- Electrical copper M1E

- Copper ingots

- M1 copper ingots

- Copper cathode

- Cathode copper m2K

- Copper cathodes M0k

- Copper cathodes M00k

- Copper Cathodes M1k

- Copper powde

- Copper nanopowder

- Copper powder superfine PMVD

- Ultrafine copper powder PMU and others

- Electrolytic copper powder

- ICP-1 Copper powder

- Cooper grid

- The alloy of copper-phosphorous

- Copper phosphorous MF9

- Phosphor copper MF10

News

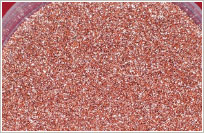

Ultrafine copper powder PMU and others

Copper soot mark designated IMC. This powder brand manufactured by the method of melt-spraying. Ultrafine copper powder - a product of manufacture using the latest technology. It consists of oxygen-free copper having a stable isotope composition of natural and non-layered structure. This kind of powder is non-toxic and non-radioactive, contains not contain precious metals. Sale copper ultrafine powder is performed using the PET bottles (200) and in glass flasks. Each batch of copper soot is made of one main batch of the starting material. Flour copper ultrafine IMC characteristics: -Degree purity of the bulk of 99.999%. Is the mean mass of a particle size not greater than 7 microns. Copper particles of soot are spherical. Is the chemical purity, which determines the ultrafine copper powder 99.996% oxygen-content in the ultrafine powder 0.06%. Is the specific radioactivity, which has a brand powder PMU - 1.1. -By The content of isotopes of copper ultrafine powder PMU - CU65-30.91%, CU63-69.09%. Nowadays ultrafine copper powder brand PMU is widely used in various industrial fields: automotive and aviation, electronic, chemical, instrument. ultrafine copper powder is used in the manufacture of various products from metal and special inks.

Soot (particles of 1-500 nm) are an artificial product, the use of which modern industry is promising. Developed revolutionary methods of obtaining the material, which are divided into chemical and physical. Especially popular obtaining powders in the atmosphere of inert gas and air, the technology of electric explosion, plasma chemical synthesis and others. These powders are produced by a number of specifications and useful armor protection, filters, structural and lubricants, pastes, abrasives and others. In particular Superdispersed extremely popular raw material to create fine abrasive pastes due to the high viscosity, strength, hardness, heat resistance, adsorption capacity. These parameters are significantly higher than the less dispersible powders. Widely applicable ultrafine tungsten-based materials. This is because ultrafine tungsten powder differs extraordinary hardness. Ultrafine WO3-based materials are produced for a variety of specifications. Ultrafine carbide consists of a spherical particle size of

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|