Production plant L-lysine, Gluten, Alcohol, DDGS, CO2

- Agriculture

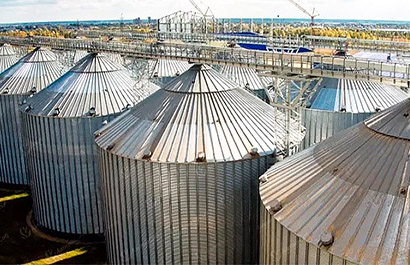

- Our Elevators

- Our Certificates

- Our Diplomas

- Organic certification

- European Certification

- Halal Certification

- Wheat - Wheat flour - Mills

- Buckwheat - Buckwheat flour

- Linen Seeds

- Corn – Сorn flour

- Oats – Oat flour

- Rye – Rye flour

- Barley – Barley flour

- Sunflower seed

- Chickpeas, Peas – Pea flour

- Beans

- Soybean seeds

- Pumpkin seeds

- Rape seeds

- Sugar beet pulp

- Beer pellets

- Meal for animal feed

- Production plant L-lysine, Gluten, Alcohol, DDGS, CO2

- Sugar Factory

- Oil Extraction Factory

- Rice Processing Plant

- Milk Powder Production Plant

- Meat Processing Plants

- Fruit Storages

- Bioproducts Plant

- Malt plant

- Cheese production plant

- Aquaculture feed production plant

- Cold Storage and Meat Processing Plants

- Cattle - meat beef

- Pig breed - Pork meat

- Sheep breeds - lamb meat

- Poultry meat

- Chicken egg

- Quail

- African chicken, cisar hen

- Geese meat

- Our beegarden

- Honey

- Bee products

- Gardens

- Containers, packaging and calibration

- Factory for the production of juices and tomato paste.

- Quince

- Pear

- Peaches

- Plum

- Cherry

- Apples

- Apricot

- Berries

- Grape

- Figs

- Mulberry

- Nuts

- Almond

- Watermelon cultivation technology

- Melons

- Transportation

News

Production plant L-lysine, Gluten, Alcohol, DDGS, CO2

«BITimpex Anstalt LTD»Today it is one of the largest producers of amino acids in Russia. A high-tech enterprise for deep processing of wheat, corn, rye with a capacity of more than 290,000 tons of grain per year. It is one of the largest investment projects in the south of Russia - a project of federal significance in the Stavropol Territory.

Main feature«BITimpex Anstalt LTD»consists in using our own environmentally friendly raw materials (wheat, corn, rye) grown in the fields of Stavropol Krai, Krasnodar Krai, Rostov Oblast, and the Republic of Crimea in production chains. Modern technologies allow us to create safe, modern, and highly effective quality products that are in demand in foreign markets, the CIS markets, and the Russian markets.

Today the enterprise produces: feed L-lysine sulfate, food ethyl alcohol of the classes "Lux", "Alpha" and "Extra", wheat gluten, feed stillage (DDGS), food carbon dioxide (liquefied CO2).

At each stage of our production, the company conducts research on the compliance of our products with the established high standards of quality and safety. For this purpose, the enterprise has six high-tech laboratories, whose employees have special education, have undergone special training and, with the help of modern equipment of the SIEMENS brand, are able to identify even the most minor deviations in the chemical and biological composition of the product at any stage of production.

Our products are in demand in markets in those industries where high quality components play a key role in production: livestock farming, poultry farming, sheep farming, production of all kinds of food products, pharmaceutical industry, chemical industry, mechanical engineering and many other areas.

Feed L-Lysine Sulfate

Feed L-Lysine sulfate — is available in dry and liquid consistency. It is one of the essential amino acids used in livestock farming, poultry farming, feed production and premix production. The use of lysine concentrate as a feed additive allows to significantly increase milk yield by 15-25%, ensure weight gain of animals and birds by 10-30%, increase egg production of hens by 10-14%. Feed Lysine helps to strengthen the bones of animals and birds, as it increases the level of absorption of calcium and phosphorus, stimulates the production of red blood cells — erythrocytes — providing internal organs with a sufficient level of oxygen.

Another positive feature of L-Lysine is its participation in oxidation-reduction processes in the body of animals and birds. Lysine also participates in synthesis and is a regulator of metabolism in the body.

By purchasing the feed concentrate L-Lysine, you receive a pure, synthesized and environmentally friendly feed additive of the highest quality, created from our own raw materials using modern technologies for deep processing of grain.

The production of high-quality dry feed concentrate L-Lysine is a technically and technologically complex process, where the quality of the final product directly depends on many factors: the indicators of the initial raw materials, storage conditions, and processing principles. The plant is a modern high-tech manufacturer of feed Lysine with a capacity of 70,000 tons of finished product per year.

The products comply with GOST R 56913-2016

Characteristics of L-Lysine 75 %

Appearance - Small granules

Color - From light brown to dark brown

Odor - Absent or slightly specific

Size: residue on a sieve with d=2 mm, no more than - 0.45 %

Size: residue on a sieve with d=5 mm, no more - not allowed

Mass fraction of lysine in terms of absolutely dry matter, not less than - 60.0 %

Solubility in water - moderately soluble

Mass fraction of moisture, no more than 5.5 %

Mass fraction of crude ash, no more than - 3.5 %

Cadmium, no more than - 0.31 mg/kg

Arsenic, no more than 1.8 mg/kg

Mercury, no more than - 0.1 mg/kg

Lead, no more than - 4.8 mg/kg

Strontium 90, no more than - 50 Bq/kg

Cesium 137, no more than - 250 Bq/kg

Toxin-producing anaerobes - Not allowed

BGKP - Not allowed

Salmonella bacteria - Not allowed

Total bacterial contamination, no more than - 5*10⁵ CFU/g

Characteristics of L-Lysine 70 %

Appearance - Small granules

Color - From light brown to dark brown

Odor - Absent or slightly specific

Size: residue on a sieve with d=2mm, no more than - 0.6 %

Size: residue on a sieve with d=5mm, no more - not allowed

Mass fraction of lysine in terms of absolutely dry matter, not less than - 58.0 %

Solubility in water - moderately soluble

Mass fraction of moisture, no more than - 6.7 %

Mass fraction of crude ash, no more than - 4.0 %

Cadmium, no more than - 0.37 mg/kg

Arsenic, no more than 2.0 mg/kg

Mercury, no more than - 0.12 mg/kg

Lead, no more than - 6.0 mg/kg

Strontium 90, no more than - 50 Bq/kg

Cesium 137, no more than - 255 Bq/kg

Toxin-producing anaerobes - Not allowed

BGKP - Not allowed

Salmonella bacteria - Not allowed

Total bacterial contamination, no more than - 5*10⁵ CFU/g

The finished product is packed in 25 kg bags (pallet weight 1 ton) and Big Run.

Wheat gluten or dry gluten

Wheat gluten or dry gluten is an environmentally friendly and modern product that is necessary to improve the quality of flour - to restore its protein composition and improve the characteristics of the dough.

Essentially, dry wheat gluten is a plant protein that is widely used by food manufacturers. It increases the volume of finished products and increases their shelf life, which allows for an extended shelf life of products.

The main consumers of gluten are flour mills and bakeries, aqua feed manufacturers, the pasta industry, confectionery manufacturers, and manufacturers of vegetarian sausages and semi-finished products.

Due to the fact that the plant has a closed production cycle, we have the opportunity to control the quality of the product at all stages: from the receipt of the original wheat raw material (grown in our own fields) to the stage of packaging and storage of the finished product in a warehouse equipped with equipment for controlling humidity and air temperature.

Modern production lines allow us to produce high-quality dry wheat gluten that meets the requirements of GOST 31934-2012, with a volume of 40,000 tons per year.

Wheat gluten is a quality product that already competes on international markets and is exported to partners in the Middle East, Asia, Africa and the CIS. Representatives from other countries have already expressed interest in the product.

Wheat gluten grade A (requirements of GOST 31934-2012)

Appearance - Powder product

Colour - Cream to yellow or light brown

Smell - Characteristic of wheat gluten, no foreign smell

Mass fraction of moisture, no more than - 7 %

Mass fraction of total ash calculated on dry matter, no more than - 2.8 %

Mass fraction of protein in terms of dry matter, not less than - 80 %

Mass fraction of particles larger than 200 microns, no more than - 1.5 %

Agglomeration time, no more than - 35 sec.

Water absorption capacity, not less than - 165 %

Food grade ethyl alcohol "Alpha", "Lux" and "Extra"

Food grade ethyl alcohol "Lux", "Alpha" and "Extra" is a modern and safe product of deep processing of environmentally friendly wheat raw materials. It is a monoatomic rectified food alcohol with the formula C2H5OH.

Highly rectified ethyl alcohol has the widest range of applications: in the production of liquor, in cooking, in the production of medicines and medical products, as a disinfectant (or its component), in the chemical industry and the perfume industry.

The largest manufacturer and wholesale supplier of food ethyl alcohol GOST 5962-2013

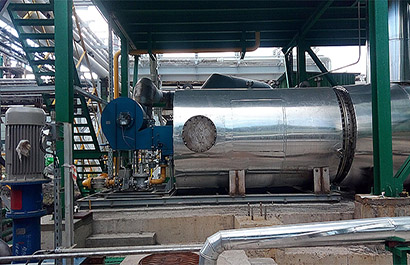

«BITimpex Anstalt LTD»is one of the largest manufacturers and wholesale suppliers of food grade ethyl alcohol "Lux alcohol", "Alpha" and "Extra". The capacity of our alcohol plant is 2,656,000 dal. of rectified alcohol per year.

Having unique and innovative technologies, we produce food ethyl alcohol of the “Lux”, “Alpha” and “Extra” classes according to GOST 5962-2013, which undergoes seven stages of purification (rectification) on modern equipment.

At all stages of production: from grain collection to the final stages of cleaning; our product undergoes careful control for compliance with established quality standards.

Alcohol is packaged by pouring into tanks.

Food grade ethyl alcohol of the "Alpha" class

Total ethyl alcohol content, not less than - 96.3 %

Purity test with sulfuric acid - Passes

Oxidation test, at 20°C, not less than - 20 min.

Mass concentration of acetaldehyde in terms of anhydrous alcohol, no more than - 2 mg/dm³

Mass concentration of fusel oil (1-propanol, 2-propanol, isobutyl alcohol, 1-butanol and isoamyl alcohol) in terms of anhydrous alcohol, no more than - 5 mg/dm³

Mass concentration of esters (methyl acetate, ethyl acetate) in terms of anhydrous alcohol, no more than - 10 mg/dm³

Volume fraction of methyl alcohol in terms of anhydrous alcohol, no more than - 0.0027 %

Mass concentration of free acids in terms of anhydrous alcohol, no more than - 10 mg/dm³

The presence of furfural is not allowed.

Food grade ethyl alcohol "Lux"

Total ethyl alcohol content, not less than - 96.3 %

Purity test with sulfuric acid - Passes

Oxidation test, at 20°C, not less than - 21 min.

Mass concentration of acetaldehyde in terms of anhydrous alcohol, no more than - 2 mg/dm³

Mass concentration of fusel oil (1-propanol, 2-propanol, isobutyl alcohol, 1-butanol and isoamyl alcohol) in terms of anhydrous alcohol, no more than - 4.5 mg/dm³

Mass concentration of esters (methyl acetate, ethyl acetate) in terms of anhydrous alcohol, no more than - 4 mg/dm³

Volume fraction of methyl alcohol in terms of anhydrous alcohol, no more than - 0.023 %

Mass concentration of free acids in terms of anhydrous alcohol, no more than - 7 mg/dm³

The presence of furfural is not allowed.

Food grade ethyl alcohol "Extra"

Total ethyl alcohol content, not less than - 96.3 %

Purity test with sulfuric acid - Passes

Oxidation test, at 20°C, not less than - 23 min.

Mass concentration of acetaldehyde in terms of anhydrous alcohol, no more than - 2 mg/dm³

Mass concentration of fusel oil (1-propanol, 2-propanol, isobutyl alcohol, 1-butanol and isoamyl alcohol) in terms of anhydrous alcohol, no more than - 5.2 mg/dm³

Mass concentration of esters (methyl acetate, ethyl acetate) in terms of anhydrous alcohol, no more than - 3.5 mg/dm³

Volume fraction of methyl alcohol in terms of anhydrous alcohol, no more than - 0.021%

Mass concentration of free acids in terms of anhydrous alcohol, no more than - 8.5 mg/dm³

The presence of furfural is not allowed.

Dry feed wheat distillers grains (DDGS distillers grains)

Dry feed wheat distillers grains (DDGS distillers grains) is a product of deep processing of wheat, which is obtained during the production of alcohol. It is a complex rich in minerals, proteins and vitamins, effectively used as a feed additive in livestock, pig and poultry farming.

The main advantage of feed mash«BITimpex Anstalt LTD»is in its concentrated consistency. The processed and purified dry mixture has a long shelf life without losing quality, unlike the unprocessed liquid version.

Wheat feed mash from«BITimpex Anstalt LTD»— a modern and high-tech product, purified from harmful impurities and ready for use in feed production. DDGS stillage is a source of such useful substances as: crude protein (in terms of a. d. v.) — not less than 25% (its efficiency is equal to the protein obtained from sunflower cake), a complex of vitamins and microelements B1, B2, B3, B4, B5, B6, B12, H (true biotin), Bc (folic acid), para-aminobenzoic acid and quarantinoids, also in feed stillage there are about 19 amino acids, zinc, manganese, copper and other minerals.

In the workshop, the feed product after distillery dregs goes through three stages:

Stage 1 – evaporation and drying.At this stage, the remaining moisture evaporates from the product. Stage 2 – granulation.The applied granulation technology allows to transform finely dispersed powder of dry stillage into granules without changing their quality indicators, ensuring their bulk storage and transportation. Stage 3 – shipment.We ship the finished product from the workshop to Big Bagi.

«BITimpex Anstalt LTD»is the largest modern high-tech manufacturer of feed after alcohol DDGS stillage. The plant's capacity allows producing up to 40,000 tons of finished product per year. Due to the fact that the technological chain of stillage production is inextricably linked with the production of ethyl alcohol of the "Lux", "Alpha" and "Extra" classes, special attention is paid to the quality of the raw materials.

In the production process, after the distillery stillage, there are two stages: drying and packaging in Big Bags. The finished product complies with GOST31809-2012

And

stored in our specialized warehouses equipped with temperature and humidity control systems to maintain the high quality of the product.

Characteristics of feed distillery grains (DDGS)

Appearance - Granules

Colour - From light yellow to brown, uniform throughout the mass

Smell - Bread-yeast, characteristic of the raw materials from which the stillage is produced, without musty, moldy or other foreign odors

Mass fraction of moisture, no more than - 8.0 %

Mass fraction of crude protein (in terms of absolutely dry matter), not less than - 26.0 %

Mass fraction of crude fiber (in terms of absolutely dry matter), no more than - 26.0 %

Mass fraction of ash curds (in terms of absolutely dry matter), not less than - 7.0 %

Granule diameter - 5-10 mm

Granule length - No more than 2 diameters

Passing through a sieve with holes d=3 mm, no more than - 5.0 %

Content of feed units in 100 kg, not less than - 92

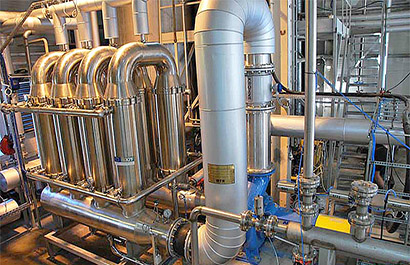

Carbon dioxide or high-pressure liquefied carbon dioxide (CO2)

Carbon dioxide or high-pressure liquefied carbon dioxide (CO2) from«BITimpex Anstalt LTD»— is a high-quality product with a high degree of purification, sufficient for the use of carbon dioxide in food production.

Carbon dioxide (CO2) is released as a result of fermentation during the production of ethyl alcohol.

Currently, carbon dioxide is used in all branches of industry: it is used in fire extinguishing systems, as a protective environment in wire welding, in the production of carbonated drinks, and also for cooling, freezing, preserving and storing food products.

As described above, carbon dioxide is a by-product of alcohol production. High-tech equipment at the plant«BITimpex Anstalt LTD» and our own environmentally friendly raw materials make it possible to obtain a safe, high-quality product that can be used in the food industry. The company's capacity allows it to produce up to 10,000 tons of CO2 per year.

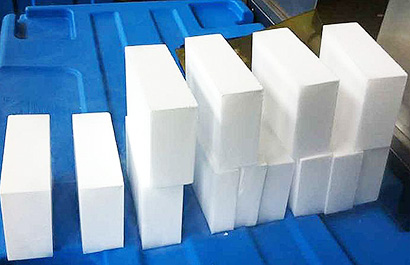

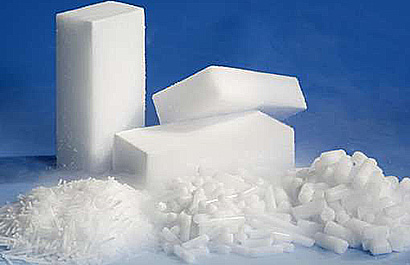

Dry ice is also carbon dioxide, which is in a solid state. Dry ice has a very low temperature, so it is widely used in the food industry. It is used for freezing and long-term storage of various food products. The temperature of dry ice is very low (up to minus 80 degrees Celsius).

The products comply with GOST 8050-85.

«BITimpex Anstalt LTD» understands the full responsibility for the environment. That is why we have invested in cleaning and compressing (liquefying) CO2, rather than releasing it into the environment.

We provide delivery of the finished product manufactured by the plant to the buyer independently. Delivery is carried out both by our own and by rail, air and water transport. All equipment has the necessary modern equipment, according to the required safety regulations and ensures the safety of the product properties.

More information and product specifications can be found in the Agriculture Catalogue.

Characteristics of carbon dioxide

Appearance - Colorless, odorless liquid, with high and low pressure, as well as in gaseous and solid states

Volume fraction of carbon dioxide (CO2), not less than - 99.8 %

Mass concentration of mineral oils and mechanical impurities, no more than - 0.1 mg/kg

Mass concentration of water vapor at a temperature of 20°C and a pressure of 101.3 kPa (760 mm Hg), no more than - 0.037 g/m3

The saturation temperature of carbon dioxide with water vapor at a pressure of 101.3 kPa (760 mm Hg) at a temperature of 20°C, not higher than - 48