Factory for the production of juices and tomato paste.

- Agriculture

- Our Elevators

- Our Certificates

- Our Diplomas

- Organic certification

- European Certification

- Halal Certification

- Wheat - Wheat flour - Mills

- Buckwheat - Buckwheat flour

- Linen Seeds

- Corn – Сorn flour

- Oats – Oat flour

- Rye – Rye flour

- Barley – Barley flour

- Sunflower seed

- Chickpeas, Peas – Pea flour

- Beans

- Soybean seeds

- Pumpkin seeds

- Rape seeds

- Sugar beet pulp

- Beer pellets

- Meal for animal feed

- Production plant L-lysine, Gluten, Alcohol, DDGS, CO2

- Sugar Factory

- Oil Extraction Factory

- Rice Processing Plant

- Milk Powder Production Plant

- Meat Processing Plants

- Fruit Storages

- Bioproducts Plant

- Malt plant

- Cheese production plant

- Aquaculture feed production plant

- Cold Storage and Meat Processing Plants

- Cattle - meat beef

- Pig breed - Pork meat

- Sheep breeds - lamb meat

- Poultry meat

- Chicken egg

- Quail

- African chicken, cisar hen

- Geese meat

- Our beegarden

- Honey

- Bee products

- Gardens

- Containers, packaging and calibration

- Factory for the production of juices and tomato paste.

- Quince

- Pear

- Peaches

- Plum

- Cherry

- Apples

- Apricot

- Berries

- Grape

- Figs

- Mulberry

- Nuts

- Almond

- Watermelon cultivation technology

- Melons

- Transportation

News

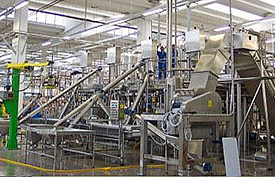

Factory for the production of juices and tomato paste.

"BITimpex Anstalt LTD"

is a national-level company with 100% foreign investment, one of the largest enterprises in the Russian Federation. Factory"BITimpex" offers consumers the following products: tomato paste, purees, jams, sauces, ketchups and juices.All products produced by our factories are without preservatives, without added sugar, without salt, without starch, other additives and without GMOs. Productsplant "BITimpex" high quality and consistentguests:GOST R 14192-1996, GOST R 31712-2012, GOST R 31755-2012, GOST R 32063-2013,GOST R 32100-2013, GOST R 32101-2013, GOST R 32103-2013, GOST R 32105-2013,GOST R 32129-2013, GOST R 32876-2013,GOST R-32876-2014,GOST R 13799-2016, GOST R 26323-2016, GOST R 34130-2017, GOST R 3343-2017, GOST R 34459-2018, GOST R 32131-2021and international HACCP standards (ISO 22000-2018). The manufactured products are packaged in glass containers. Shipment is also carried out in metal packaging of 5 kg. 10 kg. 25 kg. and 230 kg. The sophisticated packaging design will not leave any buyer unnoticed.

Product types:

- Tomato paste GOST R 3343-2017, tomato paste 25-28%, 29-32%, 36-38%, Brix. AnyBrix value for individual order.Hot/Cold BreakAny manufacturing method for individual order.2.1-2.3 Color A/B.Optimal color value for tomato paste with minimal variation.

- 100% concentrated and freshly squeezed juices GOST R 32876-2013 (tomato juice, grape juice, apple juice, carrot juice, carrot-apple juice, pear juice, pumpkin juice, plum juice, peach juice, cherry juice, cherry juice, raspberry juice , strawberry juice, blackcurrant juice, orange juice, banana juice, mango juice, pomegranate juice, gray fruit juice, pineapple juice, nectarine juice, cranberry juice, sea buckthorn juice, apricot juice).

- Sauces GOST R 31755-2012 (mushroom, fish, meat, spicy tomato, soy, tkemali, satsebeli).

- Ketchups GOST R 32063-2013 (for grill and barbecue, Crimean tomato, chili, classic).

- Puree GOST R 34459-2018 (carrot, squash, pumpkin, pear, plum, peach, apricot, orange, pineapple, nectarine, strawberry, cranberry, black currant).

- Candied fruits GOST R 34130-2017 (grapes, apple, pear, quince, peach, apricot, plum, blackcurrant, cherry, sweet cherry, orange, pineapple, strawberry, cranberry, banana, mango, papaya, carrot, zucchini, zucchini, pumpkin, beets, watermelon and melon rinds, tomatoes).

- Jams GOST R 31712-2012 (apple, pear, grape, plum, peach, apricot, orange, pineapple, strawberry, mango, carrot, papaya).

Factory "BITimpex" is located between the villages of Orlovka and the village of Kacha in the Kachin Valley, Crimean region, Russian Federation.

- The plant area is 32 hectares,

- Production area 32,000 square meters,

- The warehouse area is 45,000 square meters for 75,000 flight seats.

- The volume of production is 47,000 tons per month.

- Number of employees: 210 people.

Company "BITimpex" has 38,000 hectares in its land bank. Land under orchards, berry lands and irrigated areas for crops and growing vegetables for the smooth operation of the plant.

Factory "BITimpex" equipped with modern equipment (NAVATA Group and Cavalieri Food Processing Equipment). The plant has 9 lines for processing raw materials, independent from each other, with their own processing, packaging and packing. The lines are automated, the equipment operates automatically with a small number of employees. Availability of our own high-tech laboratory, accredited in “ROS quality” by the Ministry of Agriculture of the Russian Federation, equipped with unique equipment (Hunter Associates Laboratory). This allows us to carry out quality control at the highest possible level in all areas of production of all manufactured products.

The BITimpex plant is equipped with the following lines:

Fruit lines

For fruit processing, there are machines and lines for all types of continental and subtropical fruits: stone fruits, stoneless fruits, citrus fruits, subtropical fruits. The scheme refers to a line with maximum flexibility, and not optimized for a specific product. The resulting products can be natural, concentrated, pasteurized or sterilized purees or juices.

Ketchup lines

Ketchup production begins with storing the basic ingredients, which are: tomato paste, glucose, oil, vinegar and other products in liquid or powder form.

For high-performance lines, glucose is supplied separately, starting with crystalline sugar.

Formulation ingredients are dosed using flow meters if they are transferred by pumps, gravity powder dispensers, or other inline weighing-dosing systems.

Lines for preparing creams and sauces

This installation has a cutter that can operate under vacuum or with direct or indirect heating.

The solid portion of the formulation is prepared and weighed separately, usually on trays and fed into the cutter.

Liquids are dosed directly into the cutter using a flow meter or can be added to solids directly into the trays.

The cutter also allows you to work under vacuum, preventing oxidation and loss of color of vegetables.

After the cutter, the products are then sent for pasteurization or directly for packaging.

The product, packaged in containers, is then pasteurized in a tunnel or sterilized in autoclaves.

Candied fruit preparation lines

Preparing candied fruits involves replacing the water contained in the fruit with sugar.

The process relies on osmosis - immersing fruit in sugar syrup - and requires a long time if done in open tanks.

To reduce the time of osmosis, this process is done under vacuum: while the product absorbs sugar from the syrup, the concentration of sugar syrup decreases and in order to return it, some of the water must be evaporated from the product.

The dissolution tank is used to prepare syrup.

We have two types of machines for preparing candied fruits: a vertical type with perforated baskets (fruits are loaded into baskets) and a horizontal type, where the fruits are in a free state.

The product is loaded into the candied fruit preparation machine with glucose, which is added to increase evaporation.

When the process is completed, glucose is discharged first and stored for the next process of preparing candied fruits, and the candied fruits are placed in tanks for subsequent packaging.

After packaging, containers with candied fruits undergo pasteurization in a tunnel.

Jam making lines

The basic ingredients for making jams are fruits, sugar and pectin.

Fruits can be fresh, IFZ (individual quick frozen) or frozen in blocks.

Fresh fruit or IBZ is loaded directly into the infeed screw conveyor and the frozen blocks are first crushed.

All products are dosed in a pre-heating tank to bring them to the concentration temperature.

Pectin and citric acid dissolve in an aqueous solution.

The mixture of product and sugar then goes to a concentrator, where concentration occurs with the addition of pectin and citric acid.

If the product is not very sensitive to heat, it can be pasteurized in the same concentrator.

Before starting work, all plant employees undergo special sanitary treatment in a specially designated building in individual cabins. After the end of the work process, a similar procedure occurs. The company adheres to strict sanitary standards and medical recommendations.

The warehouses available at the enterprise are equipped with a gravitational storage system, which simplifies the placement of finished and packaged products, and also speeds up the unloading and loading system. A Euro truck is loaded and unloaded in 25-30 minutes.

Water in production is extracted from three artesian wells 90,130,140 meters in the area of the Bakhchisarai Kachinsky groundwater deposit using modern equipment.

The process of making juice.

Reception and processing of fruits and vegetables is carried out separately by variety.

Fruit juice is obtained by crushing. The result is apple pulp (pulp). The juice is forced out of it under press pressure through a drainage system with filters. This way we get the maximum amount of juice from the pulp.

The squeezed juice is clarified by filtration at the molecular level - Ultrafiltration.

As a result of the acid, the apple's natural sugars and aromatic substances pass through the membrane. Pectins, starch, suspended particles that contribute to the cloudiness of the juice are retained and removed.

First, air is removed from the juice using a vacuum pump. Then, in the pasteurizer, rapid heating occurs to 98ºC, maintaining this temperature for 30-60 seconds. and rapid cooling. This is how we preserve as much useful substances as possible in the product - vitamins and microelements.

Filling takes place entirely in a closed, sterile space, without air access.

Pasteurized juice is poured into absolutely sterile glass containers. Aseptic filling allows you to store the finished product in glass packaging for 3 years, metal packaging (foil) for 2 years, packaging made of polymer materials for 1 year at temperatures from 0 ºС to 25 ºС.

The process of making ketchup.

First, the raw materials are prepared. Fresh tomatoes are washed using two methods:

- if the degree of earthen and plant impurities exceeds 15%, use quadruple washing technology with the addition of disinfectant solutions (water consumption for washing 10 tons of tomatoes is on average 10 m3).

- if the degree of contamination is less than 15%, use hydraulic conveyors with traps to catch mechanical impurities (water consumption is at least 2-3 l/kg of raw materials).

After washing, the raw materials are subject to inspection (removal of unsuitable tomatoes - moldy, broken, green) and sorting (selection according to degree of maturity): tomatoes move along a conveyor belt at a speed of 0.05-0.1 m/s, and workers select them. About 10 tomatoes per second are sorted on one track. Machine sorting using photoelectronic sorters is also used. Next, the tomatoes go to sizing machines, where they are divided into batches of uniform size. Types of machines: drum, cable, roller, screw, roller-belt and disk. Then the tomatoes are peeled, seeds, and sepals removed either by steam thermal or chemical means (caustic soda treatment), and then crushed.

Next, tomato paste is made from the raw materials by normalization:

- rough wiping on a rubbing machine with a 5mm sieve hole diameter,

- heating to (75±5) °C on tubular or plate heaters,

- secondary rubbing occurs first on a sieve with a diameter of 1.2 mm, where the remaining seeds and skins are removed. Then, on a second sieve (0.4 mm), rub until puree is obtained.

- pressing of waste, after which the humidity should not exceed 65±3%.

- sterilization of tomato paste. Multi-pass tubular heat exchangers are used for it: heated to 125°C, held for 70s, cooled to 85°C.

- concentration of the paste occurs through evaporation of moisture.

- cooking in vacuum evaporation units, which ensures the preservation of vitamins and coloring matter.

Finally, the ketchup is prepared. Spices are added to tomato paste (finely ground in the form of water or vinegar extract, as well as CO2 extracts) and preservatives are added to unsterilized ketchups. Next, ketchups from concentrated tomatoes are boiled for 15-20 minutes, from fresh ones - no more than 45 minutes. After cooking, the product is packaged, sealed with varnished metal lids and sterilized at 100 °C for 25 minutes. Consumer packaging should not exceed 1.0 cubic meters. dm in volume. According to the agreement with the customer, a volume of no more than 10.0 cubic meters is allowed. dm. Usually packaged in 0.2-1.0 liter containers.

The process of preparing tomato paste.

Clean, conditioned tomatoes enter the device for cutting into slices. This is necessary to facilitate subsequent grinding into a homogenized mass.

From this moment, the processes of heat treatment of tomatoes begin, and here two technologies are distinguished, one of which the production line is adjusted to.

Hot Breaking Technology - HotBreak

Using this technology, crushed tomatoes are heated to a temperature of 85°C to 97°C. At this temperature, structural fibers and enzymes (protein structures involved in the digestion process) are destroyed, which makes it possible to obtain a very viscous paste with a low concentration of dry substances. Such qualities of tomato paste are in demand when making sauces based on tomato paste. High-viscosity paste does not require additional evaporation; its consumption during filling is less, which increases the profitability of sauce production.

Cold Break Technology - ColdBreak

Using ColdBreak technology (cold separation), crushed tomatoes are heated to a temperature of 60°C to 72°C. At this temperature, the pulp is separated from the seeds and skin without destroying the structural fibers and enzymes, and the natural bright color of the tomatoes is preserved. The output is a paste with low viscosity, high concentration of solids, bright color and “live” enzymes. From such tomato paste it is possible to later recover tomato juice of high quality, close to the quality of Fresh juice. Therefore, ColdBreak tomato paste is shipped not only to processors, but also in small containers for the end consumer.

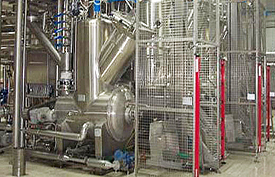

Tomato juice extraction

The heated crushed tomato mass is fed into a juice extractor, consisting of a rubbing machine with a sieve with a mesh size of mm. and a refiner with a sieve of about 0.5 mm. The first sieve retains hard fibers, peels, seeds and separates them in the form of cake, and the refiner sieve breaks the juice into smaller particles (up to 0.5 mm, depending on the replaceable sieve cell).

Making tomato paste

The resulting juice must be evaporated to a certain concentration of dry substances to reduce the cost of logistics for sale. It is sent to a vacuum evaporator. Here the most energy-intensive operation is performed - evaporation of water. The required concentration level is set on the evaporator control panel. The juice circulates in the evaporator until its concentration reaches the required level. The entire process takes place under vacuum conditions, which allows water to be evaporated from the juice at relatively low temperatures with maximum preservation of beneficial substances. The output is a thick tomato paste with a dry matter content of up to 40%. This product, in comparison with tomato juice, significantly reduces logistics costs and increases shelf life.

Brix (Brix) - dry matter content in tomato paste

Tomatoes from the garden contain 95% water and 5% dry nutrients (mainly sucrose). The percentage of dry matter in tomato paste is usually determined on the Brix scale and is conventionally called the “Brix index” or Bx. It is this indicator that is set and controlled on the control panel of the vacuum evaporator.

It is possible to produce (and do produce) tomato paste with different Brix indicators, but the market has developed in such a way that large players produce three types of paste with the following indicators:

Tomato paste Hot Break 28-30% Bx

Tomato paste with a low viscosity index and a dry matter content traditional for sauce manufacturers.

Tomato paste - Cold Break 28-30% Bx.

Tomato paste with a high viscosity index and traditional dry matter content. It has a natural bright tomato color, therefore it is used for making tomato juice. Also in demand among sauce manufacturers.

Tomato paste - Cold Break 36-38% Bx.

Tomato paste with high viscosity and high solids content. This paste is versatile due to its high Brix and is popular in cooking with end users.

The process of preparing candied fruits.

Use: food industry. The essence of the invention: the method involves preparing drying.

The objective of the invention is to increase the biological value of the finished product and give it dietary properties.

Options for implementing the method include obtaining various commercial forms of candied fruits. Thus, in the production of candied fruits for industrial processing in the confectionery and bakery industries, the raw materials separated from the liquid phase are washed with water at a temperature of 90-95oC before drying.

To produce sprinkled candied fruits, the raw materials are dried on baking sheets with atmospheric air for 2-3 hours, and then sprinkled with granulated sugar.

To produce glazed candied fruits, the raw materials are dried with heated air until the dry matter content reaches at least 80% by weight, and then glazed.

The method is implemented as follows. When preparing raw materials, all fresh fruits, berries and vegetables are sorted and washed. For certain types of raw materials, it is possible to perform additional preparatory operations.

The stems and pits are removed from the apricots and divided into halves. Cooking whole fruits with seeds is allowed for small-fruited apricots with a maximum diameter of no more than 35 mm. Apricots intended for cooking as whole fruits are pricked.

The stems and pits of cherries are removed. It is allowed to use cherries and cherries with pits. White and pink cherries are blanched in water at 80-90oC for no more than 3 minutes, then cooled in running water.

Figs are boiled with whole fruits with the stalks removed, and first blanched in water for no more than 5 minutes at 90oC.

The stalk of the dogwood is removed, after which the fruits are blanched in 10% sugar syrup for 1 minute at 100oC. Blanching in water for no more than 5 minutes at a temperature of 80oC is also allowed.

Peaches of small-fruited varieties are cut into halves, large-fruited varieties into 4-8 slices, after which the seeds are removed and peeled, and then blanched for no more than 5 minutes in water at 85oC, cooled in running water. To avoid darkening of the surface of the pulp, which is observed in some varieties of peaches, peeled fruits are kept in a 1% solution of citric or tartaric acid. It is possible to prepare peaches using the following method. After peeling, the peach slices are washed in running water and then blanched in sugar syrup of 25-30% concentration at a temperature of 85oC for 5 minutes.

The ridges and stalks of chokeberry are removed.

The stalk of plums and cherry plums (tkemali) is removed. Small-fruited plums and cherry plums are boiled with whole fruits, large-fruited plums are cut into halves and the pit is separated. Whole fruits, depending on the characteristics of the pomological variety, are subjected to one of the following types of further preparation:

blanching in water at 80-85oC for no more than 5 minutes, followed by pricking;

cutting fruits to length;

blanching for a few seconds in a 0.5% alkali solution, followed by rinsing in cold water in a continuous stream;

blanching in sugar syrup with a concentration of 25% for 1-3 minutes at 80-85oC, followed by pouring hot concentrate of clarified juice concentrate without cooling. Plum halves cannot be chopped or blanched.

Citrus and tropical fruits are cut into 2-4 parts or into circles 4-6 mm thick with peel, as well as slices, peeled and films removed. Fruits intended for cooking in halves or quarters are blanched whole for no more than 15 minutes in water at 85-90oC, and then soaked in cold water for 12 hours, after which they are cut into halves or quarters and washed again with water.

Apples, pears and quinces are peeled, seed nest and stalked and cut into slices 15-20 mm thick and at least 35 mm long; small-fruited pears and apples with a diameter of no more than 50 mm are cut into quarters. Cooking with apple skins is allowed.

The pumpkin is chopped into pieces, freed from the peel and inner film, and then cut into slices measuring 25x10x10 mm or into cubes with edges measuring 10-15 mm.

The carrots are peeled, washed with water and cut into circles 10-15 mm thick or cubes with edges 10-15 mm in size, and then blanched in boiling water for 30 minutes. It is recommended to blanch fresh carrots before cutting.

Blanch the beets for 5-10 minutes until the skin softens, peel and wash with water. Salted beets are immediately sent for cleaning. Peeled beets are cut into circles with a diameter of no more than 30 mm, a thickness of 10-15 mm, segments with a thickness of 10-15 mm, cubes with a side size of 10-15 mm.

Salted tomatoes with a diameter of less than 40 mm are cut into circles 10-15 mm thick, those with a diameter of more than 40 mm into segments 10-15 mm thick, and then soaked in running water.

Zucchini is peeled and cut with a diameter of less than 40 mm into circles 10-15 mm thick with a diameter of 40-60 mm along the axis and then into plates of the same thickness; zucchini with a diameter of more than 60 mm is peeled from seeds and cut into pieces measuring 25x10x10 mm . After cutting, fresh zucchini and pumpkin are soaked in a 1% solution of acetic acid in a ratio of fruit to solution of 2:3 for 12-16 hours, and then blanched in boiling water for 10 minutes.

Salted watermelon, melon rinds and vegetables are inspected, cut into slices or 25x10x10 mm in size, or cubes with 25 mm edges or into pieces of the same size, and then soaked for 48-50 hours in cold running water until there is no salt to taste.

The prepared raw materials are served for cooking in concentrated clarified fruit or berry juice with a dry matter content of at least 70% by weight. Cooking is carried out by analogy with cooking jam, including when using frozen fruits and berries.

When cooking candied watermelon and melon rinds, before starting cooking, they are soaked in hot concentrated clarified juice at a temperature of 90-95oC and kept for 6-8 hours. Cooking fresh watermelon rinds is allowed without standing in concentrated clarified juice.

Prepared pumpkin, zucchini, carrots, beets, tomatoes are poured with hot concentrated clarified juice at 85-90oC before cooking and kept for 4 hours. Carrots, zucchini, beets, pumpkin and tomatoes are kept in concentrated clarified juice at a pressure of 74.6 kPa before cooking. for 30 minutes, and then begin heating and cooking.

Cooking of raw materials is carried out under vacuum or without it in one or several stages.

The separated pieces of the solid phase, depending on the type of commercial form of the candied fruit produced, are subjected to further processing according to the following scheme.

When producing candied fruits for industrial processing in the confectionery and bakery industries, the raw materials separated from the syrup are washed with water at a temperature of 90-95oC, for example, in a shower with a pressure of 250 kPa for 10-15 minutes or in another way until the remaining syrup is removed from the surface, and then dried.

When producing sprinkled candied fruits, pieces of raw material separated from the syrup are dried with atmospheric air on wire trays for 2-3 hours, and then sprinkled with granulated sugar and packaged.

In the production of glazed candied fruits, the raw materials, after separation from the syrup, are dried with heated air, for example, at 40-60oC, until the dry matter content in them is at least 80% by weight, and then glazed, for example, with icing sugar.

The following concentrated clarified juices can be used for cooking: watermelon, cherry, grape, pomegranate, pear, cranberry, plum, cherry, apple with a solids concentration of at least 70% by weight, i.e. industrially produced juice concentrates that meet the requirements of the standards.

The candied fruits obtained using the described technology, depending on the type of juice used, have a chemical composition enriched with vitamins, monosaccharides, macro- and microelements. As a result of increasing the biological value of prepared candied fruits and replacing sucrose in their composition with fructose and glucose, at least partially, they can be recommended as an easily digestible dietary product to some determined population groups. In terms of organoleptic properties, the resulting candied fruits are superior to candied fruits obtained using standard technology, according to a tasting assessment, due to the milder taste inherent in the fruit and vegetable raw materials and juice used, and a more pronounced aroma characteristic of the juice concentrate used and the original fruit and berry raw materials.

Thus, the proposed method makes it possible to obtain candied fruits with increased biological and dietary value and improved organoleptic properties.

The process of making jams.

• When preparing jam, food pectin is added as gelling agent or gelling juice

• Pectin solution is prepared from dry pectin, first mixed with granulated sugar in a ratio of 1:3 or 1:5.

• A mixture of pectin and granulated sugar is poured into water with temperature 55-60 °C and stir intensively until complete dissolving pectin and obtaining a homogeneous mass.

• For 1 part of pectin take 20 parts of water.

• It is recommended to prepare the pectin solution in a mixer with turbine or propeller type mixer.

• The prepared pectin solution can be stored until consumption no more than 8 hours.

• Jam is boiled in a vacuum apparatus with a stirrer or in boilers with a steam jacket.

• Dosage, mix raw materials and sugar syrup into vacuum devices or in mixers with a stirrer.

• First, 70-75% sugar syrup is loaded, then the fruits according to the recipe are included in several turns of the stirrer to thoroughly mixing the components.

• Jam is boiled to the mass fraction of dry substances: followed by sterilization – up to 62%, and unsterilized jam – up to 70%.

• In case of insufficient acidity (pH more than 3.6) of raw materials it is allowed to add tartaric or citric acid to it in the form of a 50% solution.

• Jam is packaged in glass containers type I-82-1000 and sterilized in autoclave according to the formula 20-30-40 minutes at a temperature of 100 ° C and pressure 147.1 kPa.